Fast-track hardware and DIY order processing with AutoStore

The distribution of hardware and DIY products has experienced a strong boost in recent years, with the global home improvement market being valued at well over $800 billion (USD).

However, the industry’s profitability is currently limited by several factors stemming from the complex geopolitical scenario at an international scale. Factors like the unprecedented increase in the price of raw materials, energy costs, and problems in the supply chain represent a potential threat to hardware and DIY product distributors.

Navigating challenges in warehouse stock management

The DIY and hardware sector faces various particularities and disadvantages regarding warehouse stock management.

The most important ones are:

- Chinese DIY and hardware suppliers ship unlabelled goods generally without pallets. This presents a challenge for distributors as it slows the stock receipt process, which must be identified and correctly labelled before it can be palletised, received, and located.

- B2B channels generate orders of different natures, meaning small and large volume stock lines. This peculiarity increases in the number of trips a warehouse worker must make during picking, as storage tends to be zoned by product families or types. Therefore, preparing orders of different sizes must be managed as appropriately as possible to avoid inefficiencies in the operation. In this regard, consolidating stock in a dedicated area when resources are allocated by zone (small and large volume areas) is essential.

- For larger products, picking at height becomes a slow and costly process. Therefore, an agile replenishment process is required from height to ground level or first shelf-level picking positions. Achieving maximum efficiency in this process requires having a warehouse management system.

- For smaller products, the increase in the number of warehouse workers, long trips around the warehouse, and errors in the preparation of orders are symptoms of an inefficient preparation process. In this regard, AutoStore solutions eliminate mistakes and multiply the worker’s order preparation efficiency and speed five-fold.

- Errors in preparing orders for DIY and hardware goods are a constant source of activity in so-called reverse logistics, as they generate a significant volume of product returns.

More agility in order preparation

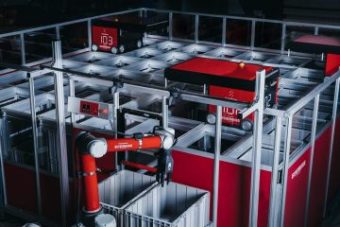

AutoStore is a suitable automated storage and retrieval system (ASRS) for DIY and hardware companies that distribute their products to traditional stores and online channels and manage products of very different sizes. For correct stock management, companies must have a native warehouse management system like AutoStore, which ensures orderly and optimal storage processes.

Integrated with a WMS system, AutoStore provides maximum efficiency in preparing high-performance goods-to-person processes. This technology, with which Element Logic has the most experience within Europe, guarantees smooth order preparation flows for hardware and DIY products, with over 200 lines per hour at each workstation. This results in a significant increase in efficiency and eliminates worker errors and their movements in the warehouse. Another great advantage of this solution is its density, allowing up to an 80% reduction in useful storage space.

Growing interest from hardware and DIY companies

DIY and hardware companies increasingly choose to integrate AutoStore systems into their warehouses. Element Logic’s team of experts and designers analyses each case to determine the solution best suited to a company’s needs.

An example is MiBricolaje.com, the largest DIY distribution network in the Canary Islands, which has decided to install the AutoStore system in its logistics centre in Tenerife. Besides saving space, this system will allow the company to increase its speed and efficiency in the picking of hardware and DIY orders, multiplying its picking efficiency by ten and reducing almost any kind of error to zero. This way, the company will improve service quality and distribute faster to the more than 600 hardware stores and shops it supplies throughout the eight islands.

Similarly, the hardware and DIY product provider Peterhans Handwerkercenter decided to install AutoStore by Element Logic in its micro fulfilment centre to respond to sales growth and the rapid increase in online orders. Thanks to this system, the company is managing to meet same-day delivery customer expectations, and reducing waiting time at store pickup counters. In addition to speeding up its picking process, the company has saved 80% of its storage space and can pick items from the system with zero errors. In this video, we explain the entire AutoStore installation process and the benefits the system brings to Peterhans Handwerkercenter.

Follow us on LinkedIn to discover new success stories and stay informed about advances in warehouse automation and robotisation at national and international levels.

If you’d like to learn more about our AutoStore solutions, contact our team today.